EMI Filter Installation Best Practices

EMI (Electromagnetic Interference) filters are a necessary component for most types of systems or equipment as it enables proper operation without interference to or from other systems. A key parameter to maintaining EMI filter performance is proper installation. Grounding/bonding, wiring, and mounting each play an important role in achieving maximum filter effectiveness.

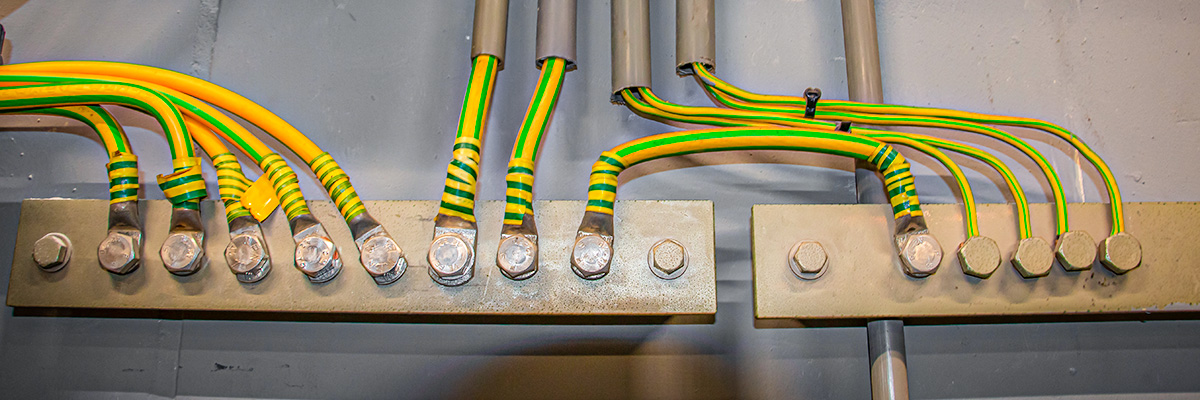

Grounding/Bonding

EMI filters are to be properly grounded/bonded to the host equipment to achieve optimum performance and meet safety requirements. The main factors to consider are as follows:

- Ensure filter housing is bonded to host cabinet via metal-metal connection. All surfaces are to be conductive and void of paint or other insulating material.

- For non-metal housings and/or cabinets, the filter is primarily grounded via the incoming safety wire. Make sure this wire is as short as possible upon entry into the host equipment. In addition, any connections to cabinet metal frame elements are to be made with flat braid instead of wires. This will help to achieve a low impedance ground/bond at high frequencies.

- As redundant safety wire connections are often required in addition to the metal-metal bonding of the filter housing to the host cabinet, make sure that the ground connections are as short as possible. Use a flat braided ground strap, if required, as it provides increased surface area.

Filter Wiring and Cable Layout

Proper control of wires and cables is essential in maintaining the performance of an EMI filter by reducing alternate noise paths. A few key considerations are as follows:

- Maintain physical isolation and separation between filter input and output wires. Make sure filter output wires are not routed close to or next to the input wires.

- Make sure to keep power wiring separate from control wiring. Power and control wires must not run in parallel. Keep control wires away from the incoming power lines to the filter.

- Route wires next to the host cabinet’s metal surfaces. This will help to decouple noise from the wires.

- If necessary, use shielded wiring to protect the filter input wires from radiated noise and terminate both ends of the shield of shielded cables.

EMI Filter Mounting

An EMI filter’s performance is also dependent on proper mounting, as follows:

- Locate the filter as close as possible to the entry point of the input power wires.

- For optimum performance, bulkhead mount the filter to the host cabinet. This will eliminate any required input wiring into the system.

- In case bulkhead mounting is not possible, make the input wires or cables are as short as possible and if required, shield them.

- Depending on the system, additional filters may be required where the EMI sources are located.

- Place cables away from the known sources of noise in the system.

- Mount the filter directly to the host cabinet metal surface. Make sure all mating/bonding surface are conductive.

Wrapping up

Implementation of proper installation techniques ensures an EMI filter will perform as designed. At Premier Filters, we bring over 35 years of design experience and knowledge to make sure the right filter is designed and properly installed. With a full range of AC and DC power line filters and unlimited custom capability, Premier delivers the right filter on time and on budget. To know more about our EMI filter solutions, email us at info@premieremc.com.