The History of Radio Frequency Interference and Causes

Radio frequency interference, commonly known as RFI, is a term that harkens back to the onset of telegraph lines and radio towers. Today, RFI is encompassed by the much broader term of EMI (Electromagnetic Interference). Since the invention of the transistor, electronic devices have incorporated high frequency switching techniques to transform power and enter in the digital age. Today, this technology is used in almost every device that can be found in our homes, offices, cars and airplanes.

With the digital age comes greater sensitivity of circuit operation to externally generated RF or EMI noise. These circuits can operate at millivolt and microvolt levels making them vulnerable to even low levels of induced noise. Have you ever wondered why you need to shut off your mobile phones when the plane takes off or lands? Or why your car radio produces a buzzing sound just before your mobile phone rings? It is because electronic devices that operate within the crowded landscape of frequencies interfere with each other.

The presence of unwanted signals or noise generated by power and digital fast switching circuits is increasing at a rapid rate. This noise can conduct down power lines as well as radiate from power and signal lines and couple into other equipment. Military and commercial standards have been created to establish noise limits that an equipment can conduct and radiate. The test frequency range is very broad and is primarily concerned from 10Khz to 10Ghz.

In the design of electronic products, EMI or RF interference must be addressed at each stage of product development. From initial analysis to board layouts and circuit topology and ICs used. Therefore, determining compliance and defining the techniques and materials to be used to mitigate an equipment’s emissions and susceptibility vulnerability is critical. In general, two of the more prominent techniques involve the use of shielding and filtering.

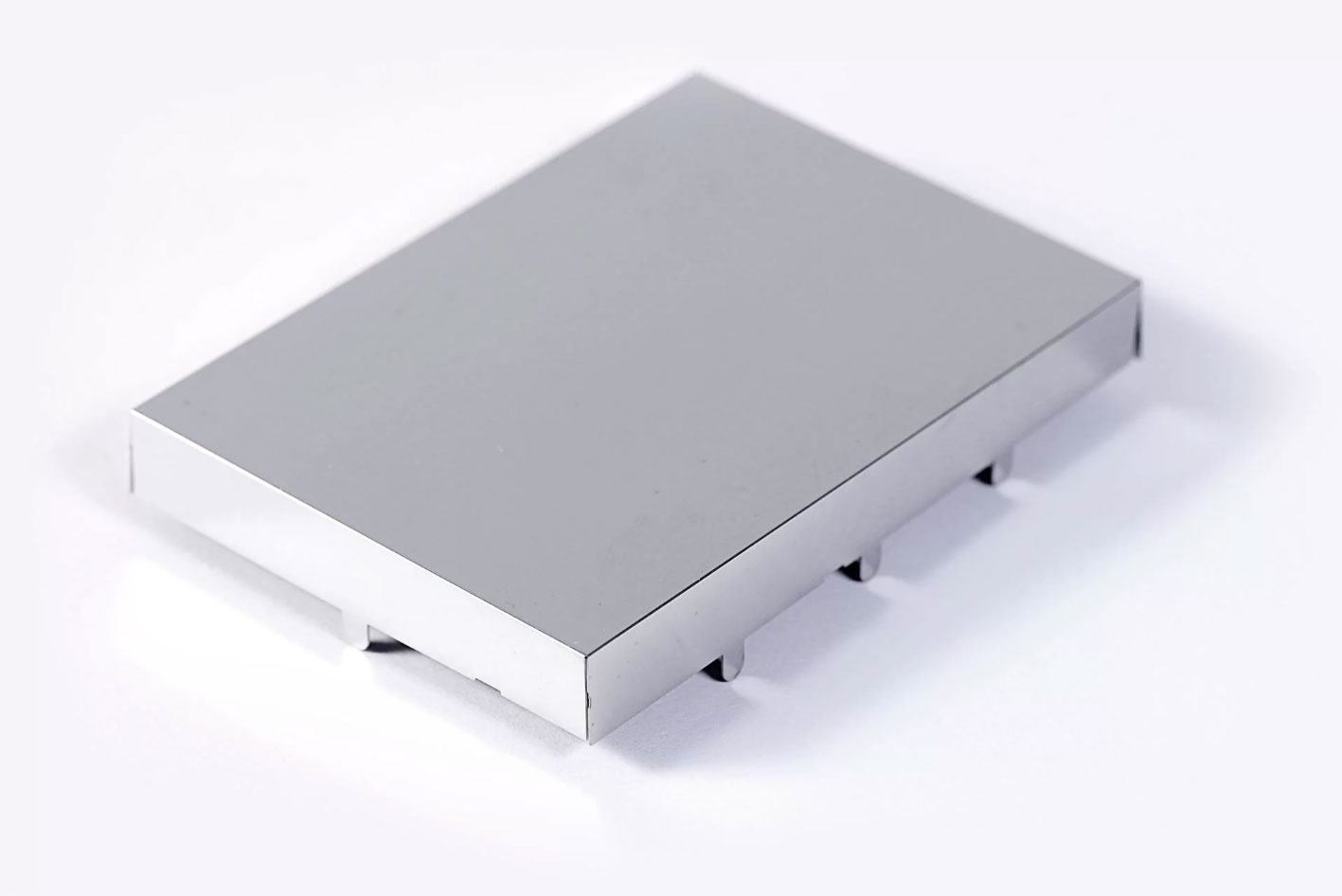

RF shielding incorporates the use of metals to reflect and/or absorb radiated noise so that it does not radiate into the surrounding environment. In addition to the metal used for the chassis or box design, bonding, penetrations and openings must be designed in order to maintain the overall shield integrity. Additional techniques include PCB design, cable routing and shielding, grounding and circuit compartmentalization.

The use of EMI filters is critical in controlling noise generated within a PCB and at equipment power and signal egress points. The majority of designs incorporate passive techniques using capacitors and inductors. These components are designed to provide mismatched circuit impedances to contain noise voltages and currents within an equipment or system so that they do not propagate into the external environment.